Nānā nui

304 kuhiliʻole kila he 'ano o ke ao holoʻokoʻa kuhiliʻole kila mea, rust kū'ē ua ikaika ma mua o 200 moʻo o kuhiliʻole kila mea, kiʻekiʻe wela kū'ē 'oi aku ka maikaʻi, hiki ke piʻi i 1000-1200 degrees.304 kuhiliʻole kila maikaʻi corrosion kū'ē a me ka corrosion kū'ē ma waena o grains. He kūpaʻa maikaʻi ka corrosion i ka hopena alkaline a me ka hapa nui o nā ʻakika organik a me nā mea ʻole.

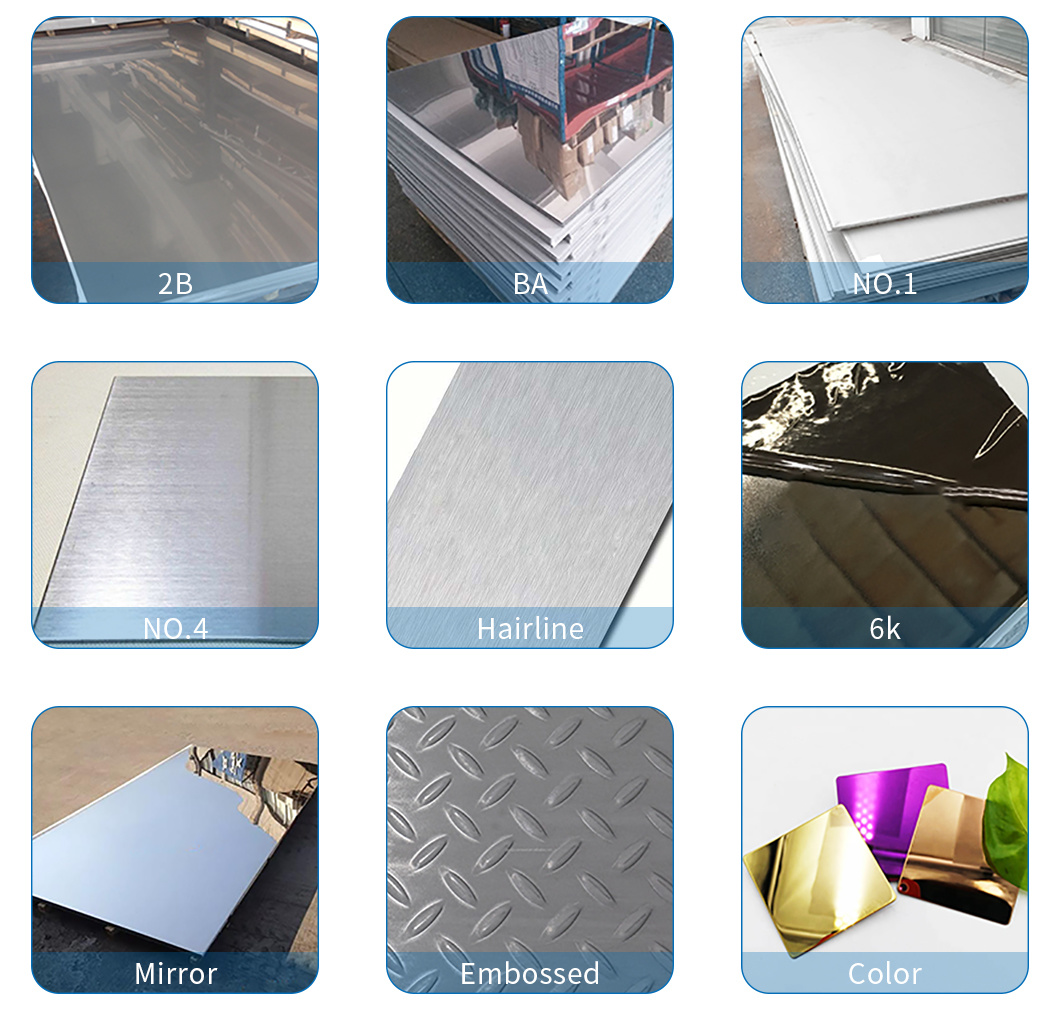

Hōʻike

| Hoʻopau ʻili | wehewehe |

| 2B | Hiki ke hoʻohana pololei ʻia kahi hoʻopau ʻālohilohi, ma hope o ka ʻōwili anuanu, e ka mālama wela, a i ʻole ma ke ʻano he hana mua e polish. |

| 2D | He ʻili ʻeleʻele, i loaʻa mai ka ʻōwili anu e ukali ʻia e ka annealing a me ka descaling. Hiki iā ia ke loaʻa i kahi ʻōwili māmā hope loa i nā ʻōwili i hoʻomaʻamaʻa ʻole ʻia. |

| BA | Hoʻopau Annealed Bright i loaʻa ma ka hoʻopili ʻana i ka mea ma lalo o ka lewa i ʻole e hoʻohua ʻia ka unahi ma ka ʻili. |

| No.1 | ʻO kahi ʻōniʻoniʻo, ʻoluʻolu hoʻopau, ka hopena mai ka ʻōwili wela i ka mānoanoa i kuhikuhi ʻia. Ma hope o ka annealing a me ka descaling. |

| No.3 | Hoʻopili ʻia kēia hoʻopau e ka No.100 a hiki i ka No.120 abrasive i kuhikuhi ʻia ma JIS R6001. |

| No.4 | Hoʻopili ʻia kēia hoʻopau e ka No.150 a hiki i ka No.180 abrasive i kuhikuhi ʻia ma JIS R6001. |

| Lāʻau lauoho | ʻO kahi hoʻopau nani, pale ʻia e ka kiʻiʻoniʻoni PVC ma mua o ka hoʻohana ʻana, hoʻohana ʻia i nā lako kīhini, |

| 8K aniani | ʻO ka "8" ma 8K e pili ana i ka māhele o nā mea hoʻoheheʻe (304 stainless steel e pili ana i ka ʻike o nā mea), "K" pili i ka pae o ka noʻonoʻo ʻana ma hope o ka poli. ʻO ka ili aniani 8K ka papa aniani i hōʻike ʻia e ke kila chrome nickel alloy. |

| Hoʻopaʻa ʻia | ʻO nā ʻāpana kila kila i hoʻopaʻa ʻia he mau mea nui i hoʻohana ʻia no ka hana ʻana i kahi hopena hoʻonaninani ma ka ʻili o kahi metala. He koho maikaʻi loa ia no nā papahana hoʻolālā, splashbacks, signage, a me nā mea hou aku. He māmā loa lākou, a hiki ke hana ʻia e hoʻokō i nā kikoʻī o nā noi like ʻole. |

| kalakala | ʻO ke kila kala he kila titanium i uhi ʻia. Loaʻa nā kala ma ka hoʻohana ʻana i kahi kaʻina hana PVD derivate. Hāʻawi nā ʻano ma ka ʻili o kēlā me kēia pepa i nā ʻano uhi like ʻole, e like me nā oxides, nitrides a me nā carbide. |

ʻO nā mea hoʻohana nui

1. Used no ka hana ʻana i nā ʻāpana maʻamau a no ke kahakaha ʻana i ka make;

2.Used e like me ke kiʻekiʻe precision mechanical parts of steel;

3. Hoʻohana nui ʻia ia i ke kaʻina hana wela o ke kaumaha hoʻomaha annealing ma mua o ke kulou ʻana.

4. Hiki ke hoʻohana ʻia i mea kūkulu hale no ka hana kīwila.

7. Hiki ke hoʻohana ʻia i ka ʻoihana kaʻa.

8. Hiki ke hoʻohanaʻia i kaʻoihana mea hana hale. ʻO ka ʻāpana ikehu nuklea. Lewa a me ka mokulele. kahua uila a me ka uila. ʻOihana mīkini lapaʻau. ʻO ka ʻoihana hana moku.

Hoʻohui Kimia o ke kila kuhili ʻole

| Papa | C | Si | Mn | P | S | Ni | Cr | Mo | ʻO nā mea ʻē aʻe |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 17.5/19.5 | ― | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 17.5/19.5 | ― | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | N:0.10/0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 18.0/20.0 | ― | N:0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0/15.0 | 22.0/24.0 | ― | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0/22.0 | 24.0/26.0 | ― | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N:0.10/0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N:0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/12.0 | 17.0/19.0 | ― | N≤0.10Ti:5ʷʢC+Nʣ/0.70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/13.0 | 17.0/19.0 | ― | Nb:10ʷC/1.00 |

| 904L | ≤0.020 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0/28.0 | 19.0/23.0 | 4.00/5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 ʻAi aniani kala kuihi ʻole Pepa ma S...

-

316L 2B Pepa kila kila kila

-

304 Nā Pāpaʻi Etching Pepa Kūleʻa Kūleʻa

-

430 Pepa Kuhili ʻole ʻia

-

SUS304 Pepa Kuhili ʻole

-

201 J1 J3 J5 Pepa Kuiliili

-

Nā Pepa Kuhili ʻole ʻia

-

PVD 316 Pepa kila kuhiliʻole kala

-

ʻO SUS304 BA nā Pepa Kūleʻa Kūleʻa ʻoi loa

-

SUS316 BA 2B Mea Hoʻolako Paʻi Paʻi Kuleʻaleʻa